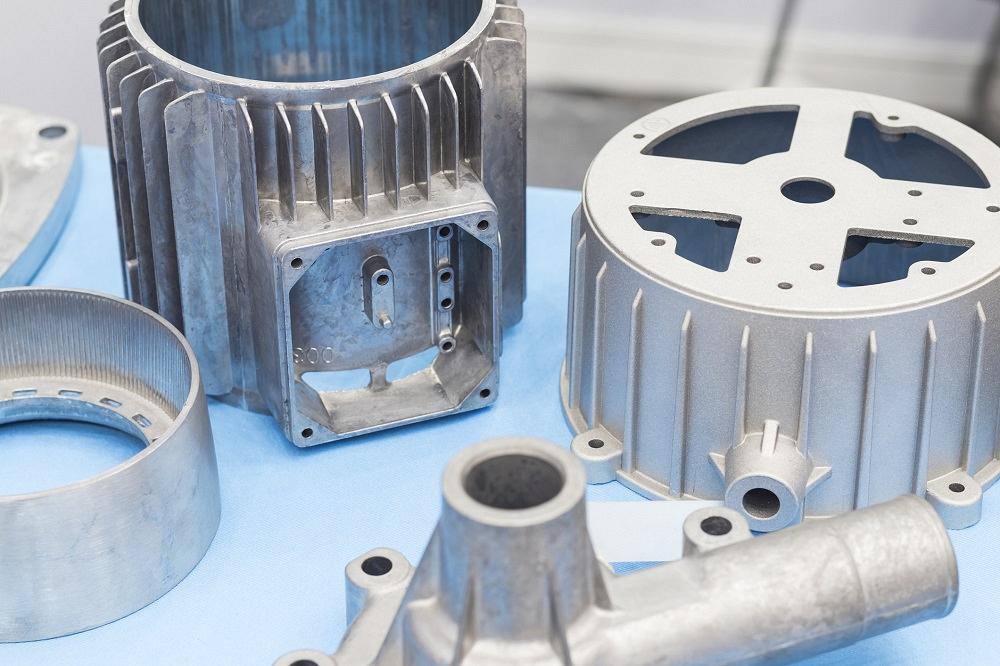

The role of Precision aluminum casting in achieving accuracy

Wiki Article

The Future of Aluminum Foundries: Technologies and trends Shaping the Market

The light weight aluminum factory market is going through substantial change. Secret fads highlight the significance of sustainability and performance. Innovations in wise production and automation are coming to be prevalent. Factories are significantly focused on utilizing recycled products. This change raises concerns concerning future practices and innovations. Exactly how will these adjustments impact production techniques and market characteristics? The answers may redefine the sector landscape in unanticipated ways.Improvements in Smart Manufacturing Technologies

As the aluminum factory market progresses, advancements in clever production modern technologies are coming to be increasingly important for improving efficiency and effectiveness. The assimilation of automation, synthetic knowledge, and the Web of Things (IoT) is transforming conventional shop operations. These innovations make it possible for real-time tracking of procedures, allowing for instant modifications that enhance outcome and decrease waste.Machine learning formulas examine production data to recognize patterns and anticipate maintenance needs, minimizing downtime. Robotics are increasingly used for recurring jobs, releasing knowledgeable employees to concentrate on more intricate difficulties. Additionally, digital doubles-- online models of physical procedures-- assist in simulations that can improve layout and operational strategies.

The adoption of these clever manufacturing modern technologies is driving competitive benefits in the aluminum shop industry. By simplifying operations and boosting decision-making capabilities, shops can meet expanding market needs while preserving top quality criteria. The future of aluminum foundries is unquestionably connected to these technological innovations.

Accepting Eco-Friendly Products and Processes

The aluminum factory market is increasingly concentrating on environmentally friendly products and procedures to enhance sustainability. This change consists of the adoption of sustainable product sourcing, energy-efficient manufacturing strategies, and effective recycling and waste monitoring methods. By integrating these practices, factories intend to decrease their environmental influence while maintaining competitiveness in the marketplace.Lasting Material Sourcing

Exactly how can light weight aluminum foundries enhance their sustainability efforts? Sustainable material sourcing has become an essential approach in attaining this goal. By focusing on recycled light weight aluminum, foundries can substantially decrease their ecological impact, as recycled products need much less energy and less sources contrasted to key light weight aluminum manufacturing. In enhancement, sourcing products from accredited vendors that abide by eco-friendly practices promotes liable mining and decreases eco-friendly influence. Shops are additionally checking out alternate materials, such as biopolymers and environmentally friendly coatings, to enhance typical light weight aluminum procedures. Teaming up with stakeholders, including vendors and environmental companies, promotes development in sourcing techniques. Ultimately, embracing lasting material sourcing not only straightens with international sustainability goals but also placements light weight aluminum factories as leaders in ecologically responsible production.Energy-Efficient Manufacturing Techniques

Light weight aluminum factories are progressively embracing energy-efficient production methods to complement their lasting material sourcing campaigns. These techniques concentrate on minimizing power consumption throughout the manufacturing procedure. Advanced innovations, such as induction melting and optimized spreading processes, are being applied to minimize the overall carbon impact. Additionally, automation and clever manufacturing systems improve operational effectiveness, enabling better power monitoring. Factories are also discovering the integration of renewable power resources, such as solar and wind, to power their procedures. By focusing on energy performance, aluminum factories not only lower production costs however also align themselves with international sustainability objectives, guaranteeing a much more ecologically responsible approach to aluminum manufacturing while meeting the increasing demand for environment-friendly techniques in the industry.Reusing and Waste Monitoring

Embracing environmentally friendly products and processes, aluminum shops are focusing on recycling and waste administration techniques to improve sustainability in their procedures. By integrating closed-loop systems, these centers are decreasing waste and optimizing source efficiency. Scrap light weight aluminum, an easily offered product, is being recycled on-site, considerably lowering the need for virgin products and lowering energy consumption. Advancements in sorting and processing modern technologies better facilitate the recycling of aluminum, ensuring that also polluted materials can be repurposed efficiently. Furthermore, factories are embracing sustainable practices such as decreasing dangerous waste and promoting making use of eco-friendly products for packaging. This commitment to reusing not just reduces environmental influence yet additionally improves the economic practicality of aluminum shops in an open market.The Duty of Automation and Robotics

Automation and robotics are significantly transforming the light weight aluminum shop sector, significantly enhancing manufacturing performance. By incorporating innovative modern technologies, shops can decrease labor costs while all at once boosting security requirements for their labor force. This shift not only simplifies procedures but additionally positions the industry for lasting growth in a competitive market.Boosted Production Efficiency

Revolutionizing manufacturing processes, the assimilation of sophisticated robotics and automation technologies has actually ended up being a keystone for aluminum foundries looking for improved efficiency. These technologies enhance workflows, minimize cycle times, and enhance product high quality by minimizing human error. Automated systems can keep an eye on assembly line in real-time, permitting instant modifications that maximize outcome. Furthermore, robotics facilitate the handling of hazardous materials, making certain safer workplace while enhancing throughput. Anticipating upkeep technologies likewise add to efficiency by expecting devices failings, thereby minimizing downtime. Because of this, aluminum shops can attain greater consistency in their items while reacting extra swiftly to market needs. This accept of automation is establishing a brand-new criterion for performance and functional quality within the industry.

Decreasing Labor Expenses

The shift towards advanced robotics and automation in aluminum foundries not just enhances production effectiveness however also plays a significant role in reducing labor costs. By incorporating automated systems, shops can lessen the reliance on manual work, which frequently involves high wages and training expenditures. Robotics simplify repeated tasks such as pouring, molding, and ending up, enabling a higher result with less personnel. This technical modification not only lowers labor-related expenses but additionally enhances consistency and top quality in production. Additionally, automation can operate around the clock, taking full advantage of operational hours without the associated prices of overtime or change differentials. Because of this, aluminum shops can accomplish significant cost savings while maintaining affordable pricing in a progressing market landscape.Improving Safety Standards

While standard aluminum factory procedures typically reveal workers to hazardous environments, the integration of robotics and automation greatly enhances security criteria within the market. Automated systems can execute high-risk tasks, such as liquified metal handling and heavy training, reducing human exposure to hazardous problems. Furthermore, robotics can run in severe temperatures and hazardous ambiences, successfully decreasing the risk of injury. Advanced checking modern technologies and expert system warranty real-time safety evaluations, enabling for prompt reactions to prospective threats. Automation simplifies process, minimizing the probability of crashes created by human mistake. Consequently, the fostering of these modern technologies not just enhances safety however likewise promotes a much more effective and reliable workplace in light weight aluminum shops.Enhancing Energy Efficiency in Production

As light weight aluminum foundries seek to keep competition in an evolving market, enhancing power effectiveness in production has emerged as a vital focus. By embracing advanced technologies such as high-efficiency melting heaters and automated temperature level controls, factories can especially lower energy intake. Applying real-time monitoring systems enables precise monitoring of energy use throughout the manufacturing process, enabling quick changes to enhance effectiveness.Additionally, moving to alternate energy resources, including renewable options, can better reduce the carbon footprint. The assimilation of energy recuperation systems, which recover waste heat for reuse, is coming to be progressively typical. Training employees in energy monitoring techniques ensures that everybody associated with the production procedure bears in mind power usage.

These initiatives not only lower operational prices however likewise straighten with global sustainability objectives, positioning aluminum foundries as accountable players in the market while enhancing their click here general competition. - Aluminum Foundry

Technologies in Recycling Aluminum

Developments in reusing aluminum have actually gained momentum along with efforts to improve energy performance in production. The aluminum market has actually embraced sophisticated technologies that enhance the reusing process, minimizing power usage and ecological influence. Techniques such as hydrometallurgy and new sorting modern technologies improve the extraction of aluminum from scrap, boosting return prices and making sure higher quality recycled material.

The growth of closed-loop recycling systems permits factories to reuse light weight aluminum without significant destruction in quality, making the process extra sustainable. Innovations in logistics and collection, consisting of boosted radar and automated sorting, have also played a crucial duty in raising the effectiveness of aluminum healing. These developments not only add to a circular economy but additionally aid minimize the carbon impact connected with light weight aluminum manufacturing. As the demand for sustainable practices expands, these advancements place the aluminum foundry industry as a leader in liable source monitoring.

Replying To Market Needs and Consumer Trends

Adaptability has actually ended up being a cornerstone for light weight aluminum shops reacting to developing market demands and consumer fads. As markets progressively focus on sustainability, aluminum shops are moving towards environmentally friendly practices, consisting of improved recycling processes and reduced carbon impacts. This shift straightens with consumer choices for ecologically liable items, driving foundries to introduce their offerings.Additionally, the surge of light-weight materials in aerospace and auto industries demands developments in light weight aluminum alloys and casting techniques. Foundries are purchasing r & d to produce high-strength, lightweight elements that fulfill strict efficiency criteria.

Personalization has actually gained traction, with customers looking for customized services. Light weight aluminum shops are leveraging advanced manufacturing modern technologies, such as 3D printing, to accommodate particular customer needs efficiently. This responsiveness not just pleases customer demands however likewise positions aluminum shops competitively in a vibrant market landscape, guaranteeing their relevance in an ever-changing industrial atmosphere.

Frequently Asked Concerns

Exactly How Do Light Weight Aluminum Foundries Impact Resident Economies?

Aluminum foundries substantially impact neighborhood economies by developing jobs, stimulating demand for local suppliers, and contributing to area growth. Their procedures often lead to raised tax obligation earnings, which can money essential public services and infrastructure improvements.What Are the Safety Rules for Light Weight Aluminum Factory Workers?

Safety laws for light weight aluminum factory workers consist of required personal safety devices, proper air flow systems, normal training on dangerous materials, and adherence to standards set by work health and safety and security managements to lessen risks and guarantee employee security. - Aluminum Casting CompanyHow Does Light Weight Aluminum Recycling Affect Global Supply Chains?

Aluminum recycling substantially decreases demand for resources, improves source effectiveness, and maintains costs. This shift effects global supply chains by cultivating a circular economic situation, promoting sustainability, and making certain a much more resistant market in fluctuating markets.What Occupation Opportunities Exist in the Aluminum Foundry Market?

Various occupation possibilities exist in the aluminum shop industry, consisting of duties in engineering, quality assurance, production administration, and r & d. Knowledgeable labor positions such as mold and mildew manufacturers and machine drivers are additionally in demand.Just How Do International Trade Plans Impact Light Weight Aluminum Foundries?

International trade policies considerably influence aluminum factories by influencing import tolls, supply chain dynamics, and market access. These aspects can affect functional costs, competitiveness, and general earnings within the international aluminum production landscape.By focusing on recycled light weight aluminum, foundries can significantly minimize their ecological impact, as recycled materials require much less power and less sources contrasted to main aluminum manufacturing. Light weight aluminum factories are significantly adopting energy-efficient production techniques to complement their sustainable material sourcing initiatives. Automation and robotics are increasingly transforming the light weight aluminum shop sector, substantially boosting manufacturing performance. The change in the direction of progressed robotics and automation in aluminum factories not only enhances production efficiency yet additionally plays a considerable role in reducing labor expenses. As aluminum shops seek to keep competitiveness in an evolving market, boosting energy performance in production has emerged as a crucial emphasis.

Report this wiki page